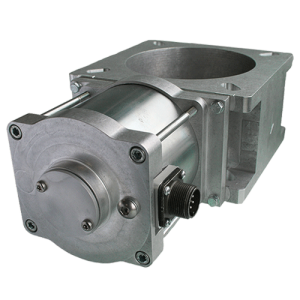

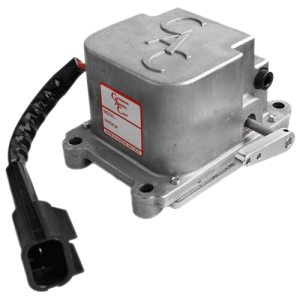

ACTUATORS

Designed To Out Live The Life Of The Engine

A high performance speed control system results when a GAC actuator is installed on an engine and electronically connected to compatible GAC governing system components. The design baseline for GAC actuators incorporates fast responses, multi-voltage usage and proven reliability to allow for more precise control.

GAC employs its field proven electromechnical design which provides proportional actuator movement based on actuator coil current.

All of GAC actuators are easy to install with no maintenance required. GAC also offers a complete line of speed control devices for use with our actuators;

all of which are 100% field-proven tested.

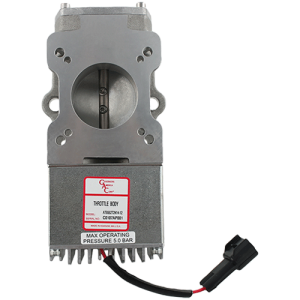

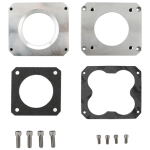

THROTTLE BODY

ATB552T2N14-12 or -24

12 or 24 VDC / 55mm / High Temperature & Sealed - 5.0 Bar, 250 F [125 C] Ambient

ATB85T4N14-24

24VDC / 85mm / High Temperature & Sealed - 5.0 Bar, 250 F [125 C] Ambient

PUMP MOUNTED

ADC100-12 or -24

12 or 24 VDC / Packard Connector without Mating Connector / Includes GA102

ACB275C

24 VDC / Military-Style Connector without Mating Connector / Specially Designed for MTU / Stop Lever LE1400-4 Included

ENGINE MOUNTED

ACD110-12 or -24

12VDC / Deutsch Connector without Mating Connector / Same as ACD110A

ALR160-S04-12

12 VDC / Packard Connector without Mating Connector // Shibaura (Perkins) N843-C, N844L-C, N844LT-C (Caterpillar C-series or Volvo D2)

UNIVERSAL

ADD104-12 or - 24

12 or 24 VDC / Packard Connector without Mating Connector / Lever Included

ACB120

Multi-VDC / Military-Style Connector without Mating Connector / Sand-Cast Housing

ACCESSORIES

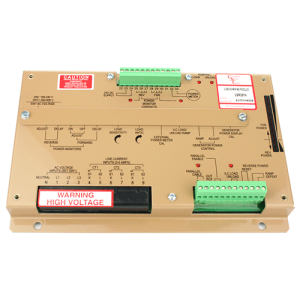

SPEED CONTROLS

CONTROL ENGINE SPEED WITH FAST, PRECISE RESPONSE

GAC’s Speed Control Units are precise speed controls designed and manufactured in various configurations to meet application requirements using the latest analog and digital control technologies. Reverse battery polarity and fail-safe protection in the event of loss of speed sensor signal or battery voltage is incorporated in every GAC Speed Control Unit. A wide variety of application needs can be satisfied with GAC’s constant or variable speed governing in isochronous or droop operation. All circuit boards are hard potted or conformally coated to be vibration and moisture resistant.

DIGITAL SPEED CONTROLS

EEG6500

(CE) Multi-VDC / Built-In Display / Terminal Strip / Gaseous or Diesel

EEG6550

Multi-VDC / Built-in Display / Gaseous or Diesel / With Speed Switch / Variable Speed 0-5VDC or 4-20mA Direct

EDG5500

(CE) Multi-VDC / Simple LCD User Interface / Fast Set-up With 5 Push Buttons, No Potentiometers

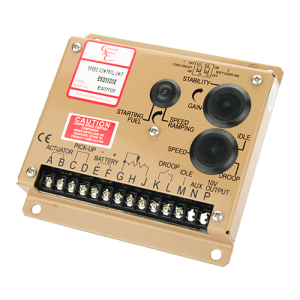

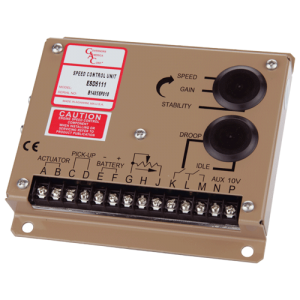

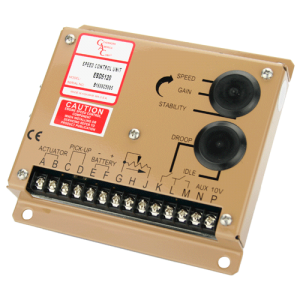

ANALOG SPEED CONTROLS

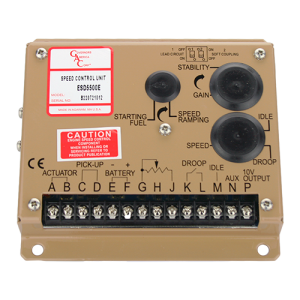

ESD5500-II

(CE) Isochronous, Droop & Variable Governing / Speed Ramping / Starting Fuel Control /Anti Wind-Up Circuit / Soft Coupling / Selectable Light-Force Capability / Dither Function

ANALOG - ACCESSORIES

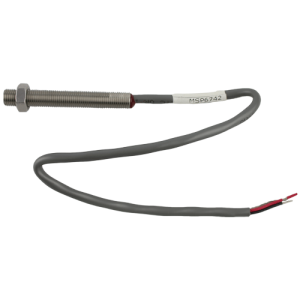

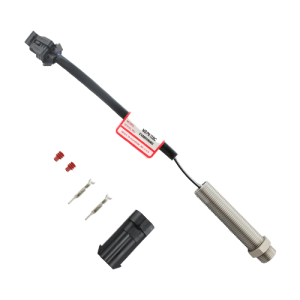

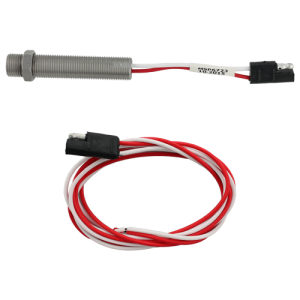

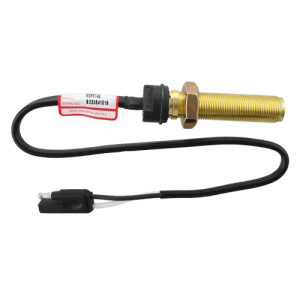

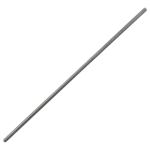

Magnetic Pick Ups

MAGNETIC SPEED SENSORS

The Magnetic Speed Sensor detects when ring gear teeth, or other ferrous projections, pass the tip of the sensor. Electrical impulses are produced by the sensor’s internal coil and sent to the speed control unit. The signal from the magnetic speed sensor, teeth per second (Hz.), is directly proportional to engine speed. Speed sensors are available in various lengths in both U.S. and metric threads. Wire leads, military connectors, packard connectors, automotive connectors or stud terminals are also available. Over 35 styles currently available.

THROTTLE BODY

MSP6744

3/4 - 16 UNF Threaded / Thread Length (2.3 in [58mm]) / Harness Length (High Output 1.2kΩ) / Connector (#8-32NC-2A Threaded Stud Terminals) / With Mating Connector (No)

MSP6715

M16 x 1.5 Threaded / Thread Length (3.0 in [76mm]) / Harness Length (na) / Connector (Military) / With Mating Connector (Yes)

ACCESSORIES

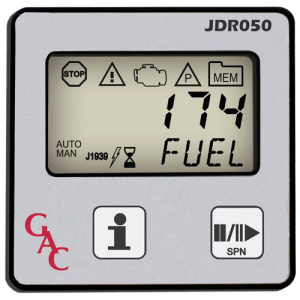

INSTRUMENTATION

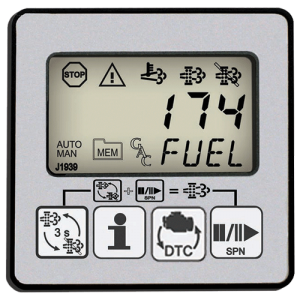

J1939 Data Readers - Wide Temperature Range with Built-In CAN bus Termination Resistor

GAC’s low-cost JDR series of J1939 data readers allow users to monitor trouble codes and standard engine parameters. More advanced models support Tier IV engines with diesel particulate filters (DPF). Harsh applications are no match for JDR’s rugged design. With installation and setup a breeze, users will be monitoring engine vital signs and configuring parameters in no-time.

INSTRUMENTATION

JDR050

J1939 Diagnostic Trouble Code (DTC) Reader / No Live Engine Data / Mating Connector Not Included

JDR100-IV

J1939 Diagnostic Trouble Code (DTC) Reader and Live Engine Parameter Reader and Diesel Particulate Filter (DPF) Regeneration Support/ Mating Connector Not Included

GECS104

(Basic Engine Protection Module)

ACCESSORIES

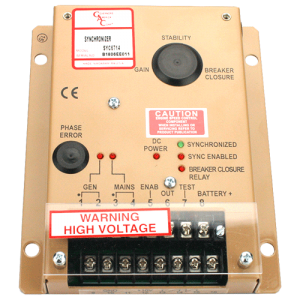

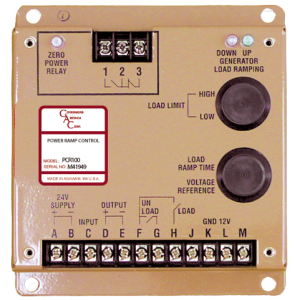

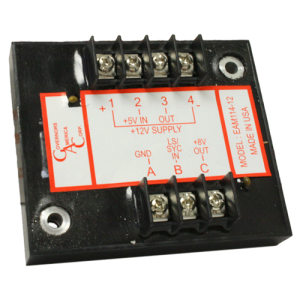

GENERATOR ACCESSORIES

GAC Generator Set Modules

The GAC provides a complete line of analog modules for generator sets. Module functions include load sharing, synchronizing, voltage regulation, speed ramping, voltage matching and a large assortment of analog modules to interface with other brands of controls such as Woodward, Cummins, CAT, etc.

LOAD SHARING AND SYNCHRONIZING

INTERFACE MODULES

EAM208

24VDC / Variable Speed DC Generator Control / Integrated Current Transformer / 200A Input / 0-8VDC Output / Built-In Power Meter Output

PRC100A

Generator Power Ramping Control

EAM114-24

(24VDC GAC Load Sharing & Synchronizing - Deutz EMR)

GASEOUS

Fuel and Ignition Management System (FIMS)

In answer to market demands, GAC offers an advanced gaseous fueled engine management system with exhaust emissions control technologies to meet the tough standards sanctioned in the United States and the rest of the World.

GAC’s total system approach results in a cost effective solution that offers the greatest potential for improvements in both engine efficiency and exhaust emissions while providing many features.

Basic Fuel and Ignition Management System (FIMS) for low pressure applications using a venturi mixer and stepper motor control valve. The user interface software is completely designed by GAC. System includes a built-in engine speed governor. Extremely cost effective and capable. System includes two separate modules which can operate stand-alone depending on the application needs.